How Does the Process Work?

In order to be recycled, film must be separated. This includes HPDE film from LDPE film, and furthermore clear films should be separated from colored and/or printed film. Film that is not separated can greatly affect the value of the film. Colored or printed film and clear film is processes on different streams in order to eliminate contamination of pellets. For example, clear film that is not separated and processed with printed materials, will create a mixed pellet dramatically reducing its potential future uses.

In addition, film that contains labels should also be separated from clean film. One U.S company has developed patented technology that cleans these films prior to being pelletized, allowing more film to be recycled on U.S. soil opposed to being shipped overseas.

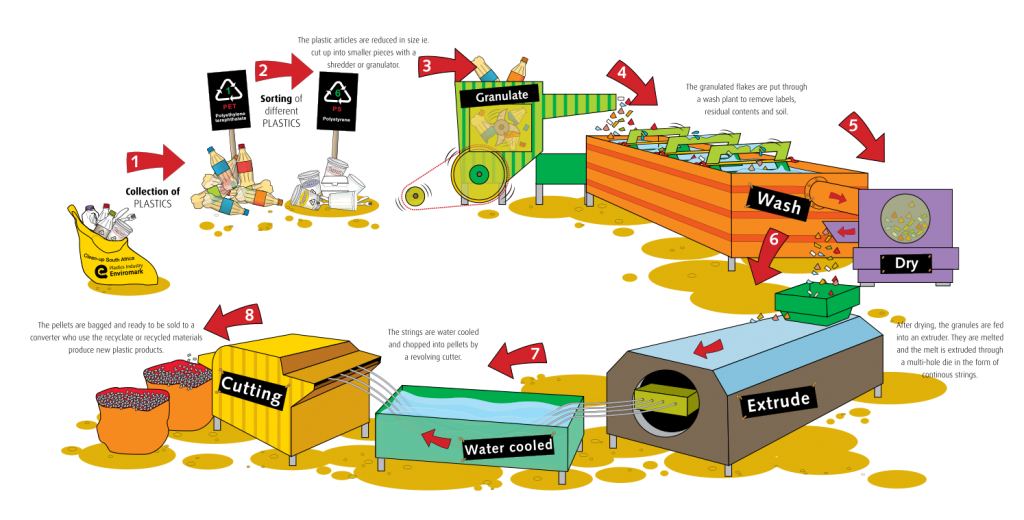

Next, LDPE film is shredded into flakes with the use of grinders. Once in flake form, the plastic is cleaned removing dirt, contaminants, and other debris. The newly cleaned bits are then dried, melted and pelletized for ease of transportation. In pellet form, the LDPE is either used on its own or combined with virgin LDPE material to produce new end-products. Many manufacturers use recycled LDPE to produce piping, trash bags, sheeting and films for building and agricultural applications, composite lumber, and other products. Recycled HDPE film is primarily used for composite lumber and plastic bags.

What are the Benefits of Recycling LDPE?

Beyond reducing waste and creating a cleaner world, there are practical benefits to companies that make the effort to recycle LDPE film.

Companies that recycle LDPE and remove the film from its trash stream, reduce the volume of waste needed to be taken away from their facility and their trash bill. Many recycling companies will help set up and organize a recycling program at your facility and pay you for the used LDPE film.

In addition, waste film takes up less space than waste corrugate, meaning less frequent deliveries and recycling pickups and therefore less gas consumed. Lastly, because LDPE is derived from natural gases it uses less energy to produce and recycle compared to corrugate.

If you’re reassessing your secondary packaging and are looking to be “greener,” don’t hesitate to consider using LDPE film. EDL Packaging Engineers is committed to sustainability, and recycles all of its LDPE film used for testing. Our engineers can help assess and identify the best way to incorporate LDPE film into the secondary packaging for your products, whether they are bundled and shrink-wrapped, or picked and placed into a tray for stability and then wrapped.

Uses of LDPE Plastic

How is LDPE Recycled?

As LDPE is heated, it turns from a solid, to a viscous gummy liquid and then to a mobile fluid as temperature is increased. The melting point of LDPE is just 115°c. Because of LDPE’s nature of having such a low density and melting point, it allows for a process called ‘float-and-sink’ to be used to separate it from the other polymer chemicals. Separation is performed in a flotation tank using water to execute the separation.

Manufacturers use polyethylene, a byproduct of oil, to create a wide variety of plastic products, from medical supplies to paper coatings. Low-density polyethylene (LDPE) provides increased pliability and decreased strength, making this material ideal for packaging applications, such as plastic bags and milk cartons. The wide use of LDPE results in large quantities of material for recycling.

Purpose

LDPE that is not recycled goes to landfill and consumes petroleum. According to the State of California Department of Conservation, over one billion LDPE water bottles ended up in California landfills in 2003. If recycled, these bottles could have used to create 74 million square feet of carpet or 16 million sweaters.

Identification

Manufacturers stamp plastics with an identifying number, ranging from one to seven, which indicate how these materials may be recycled. LDPE is identified by the recycling symbol, which consists of a triangle with three arrows on the outside, with the number 4 in the middle. Usually this recycling mark is stamped near the list of ingredients on a package. It may also be imprinted on the plastic container.

Considerations

Recyclers may find the number 4 recycling symbol on a great many products, but low densitypolyethylene most commonly is found in bottled water packaging. Shopping bags, milk cartons and garbage bags typically are created from polyethylene. Any types of plastics, which are thin and very soft, usually are formed out of low density polyethylene, so check the product carefully for the recycling symbol.

Prevention

Most neighborhood recycling centers accept high and low density polyethylene plastic recycling. Dropping LDPE products off weekly at a recycling center may reduce pollution, and lessen demand for raw materials. There are various ways to reduce the use of plastic, such as reusing plastics when possible, purchasing large drums of water (usually available outside your local grocery store), using paper bags when shopping, and shopping with cloth bags, which can be reused for years on end.